A noisy clutch – yeah, it’s one of those problems you notice when you’re stuck in five o’clock crawling down Hukanui Road, or maybe heading out to Morrinsville and you start getting that annoying rattle every time you change gears. We see it all the time at Grimmer Motors – Suzukis, Hyundai Tucsons, the odd Peugeot 308, or even someone’s hard-worked Toyota Hiace making odd noises from the clutch. It’s not just blokes either, plenty of women from Rototuna to Ngaruawahia bring their cars in with the same complaint.

A noisy clutch can be a warning something’s up under the bonnet, and if you leave it too long, you might be looking at a fat repair bill down the line. Here’s five fixes and some real Kiwi tips to help sort out a noisy car clutch – the kind of info you’ll wish you’d had before that last crawl through Dinsdale potholes sent your clutch over the edge.

1. Check and Adjust Your Clutch Pedal Clearance

First up – simple but overlooked. If you’re driving a Mazda Demio or one of those Skoda Octavias from Cambridge, your clutch pedal needs the right amount of “free play” (that little bit of movement before it starts feeling heavy). Too much or too little, and you’ll get all sorts of grinding and squeaking.

What we do: measure the pedal free play, tweak the cable or hydraulics, then road test. Not hard, but it makes a difference – especially after plenty of stop-start driving around Chartwell Shopping Centre. Want some DIY info? Check out this handy guide to adjusting the clutch.

2. Replace Worn Out Clutch Bits

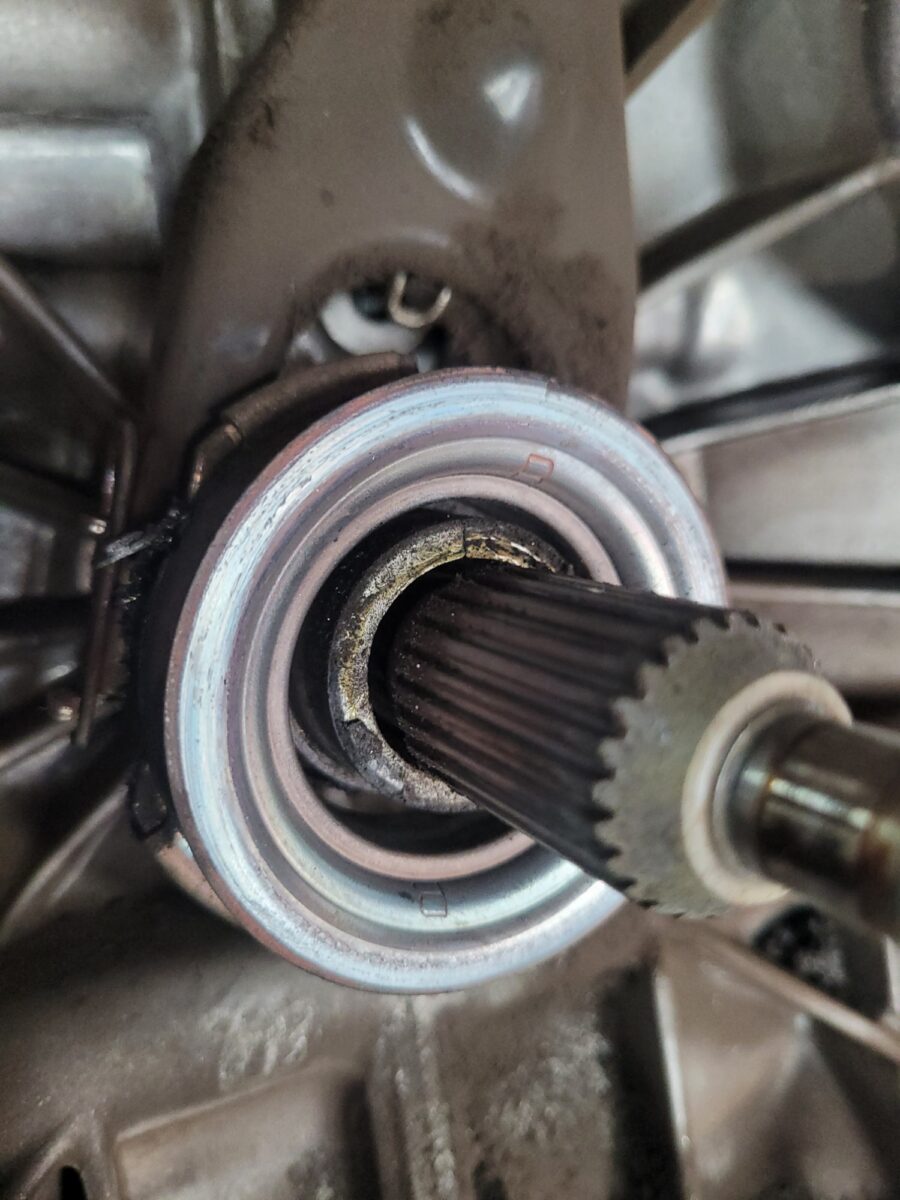

Seen plenty of noisy clutches in late-model Honda Jazzes and a few older Subarus from Te Awamutu with the same issue – the clutch disc, pressure plate, or bearing is worn out. If you’re hearing screeching, chattering, or a kind of “marbles in a tin can” sound, it’s probably time to swap something out.

We’ll pull it apart, check for clutch disc wear, pressure plate damage, or a noisy release bearing and replace what’s on its way out. If you catch it early, you’ll save yourself money. If you need more info on the right time to replace, have a nosey at this clutch replacement guide.

3. Lube Up the Linkages and Bearings

With all the dust that gets into your car driving down Ohaupo Road, plus a few wet Hamilton winters, clutch linkages and bearings get dry or sticky. This leads to squeaks, especially when things warm up in summer.

We get in there and put a bit of high-temp grease on the moving parts – not too much, just enough. Keeps everything running smooth and quiet, especially if you’re running an older Ford Mondeo or a Nissan X-Trail.

4. Check the Hydraulic System For Leaks

Plenty of clutches these days are hydraulic – especially on newer Euros (think Citroen C4 from St Andrews, or a Kia Cerato from Tamahere). Sometimes you’ll get a noisy clutch simply because there’s a leak, or a bit of air in the system.

We’ll check for leaks, top up fluid, bleed the system to get rid of any air bubbles, and make sure your clutch pedal feels right again. If you want the technical angle, have a look at this write-up on clutch hydraulics. Makes a big difference when you’re stuck doing a hundred clutch presses in Hillcrest traffic.

5. Resurface or Replace Your Flywheel

Last one – one of the noisiest clutch faults we’ve seen lately was in a Ssangyong Stavic that came in from Taupiri. Turned out the flywheel was cooked – warped and covered in hotspots from years of city driving and tow work.

Flywheel got resurfaced, car went quiet as a mouse. Sometimes you need to replace it if it’s too far gone, but often a quick tidy-up sorts it. If you’ve got shuddering or nasty grinding, worth getting it checked.

Why Bring Your Clutch Woes to Grimmer Motors?

If you’re around Hamilton or the outer towns (Pukete, Gordonton, even a few folks come in from Raglan), we’ve probably seen your type of clutch problem before. You’ll get:

-

Proper experience – Our techs know clutches on Nissans, Toyotas, Volvos, even the odd Benz.

-

Quality bits – We use good parts, not the cheapest junk. Lasts longer, runs better.

-

Straight-up service – You’ll know exactly what’s up and what it’s going to cost.

-

Handy location – Swing by if you’re running errands in Hamilton or passing through from places like Te Kowhai.

-

Full workshop – Not just clutches, we’re handy with WOFs, hybrid repair, full car service – you get the idea.

Keen to learn more about clutch repairs? Suss these out: