ABS Light Popped On? Here’s What To Do

Right, if your ABS warning light suddenly pops up on the dash while you’re crawling down Te Rapa Straight or weaving through town on Peachgrove Road, don’t stress — but don’t just ignore it either. Your car’s ABS (Anti-lock Braking System) is there to stop your wheels locking up if you have to stomp on the brakes, especially with all the stops and starts we get going through busy Hamilton traffic or on those wet winter mornings out Morrinsville way. Problems with the ABS will muck with your car’s safety, so let’s get onto it.

Run a Quick Check for Fault Codes

First up, you want to know what you’re dealing with. One of our techs will plug in a scan tool to check for Diagnostic Trouble Codes (DTCs) — these codes tell us what the ABS system’s not happy about. Could be a dodgy sensor, a wiring issue, or the module itself. If you’re into your own DIY, there’s plenty of info on how to diagnose the issue here. Don’t just keep driving with the warning light glowing, especially if you’re heading out on the back roads to Cambridge or Raglan.

Learn more about why your ABS light might be on.

Check Your ABS Wheel Sensors

Honestly, we see this one all the time with Mazdas, Audis, the odd SsangYong or Suzuki. ABS sensors sit down by your wheels, so after a few years of potholes on River Road, mud out Gordonton way, or winter trips to the Mount, you’ll end up with dirt or damage. Have a look — a quick clean might sort it, or if it’s bashed up or cracked, you’ll need a new one. These sensors send crucial info about wheel speed back to your ABS. If they’re out, the ABS won’t know what’s what.

Find out how to replace ABS wheel sensors.

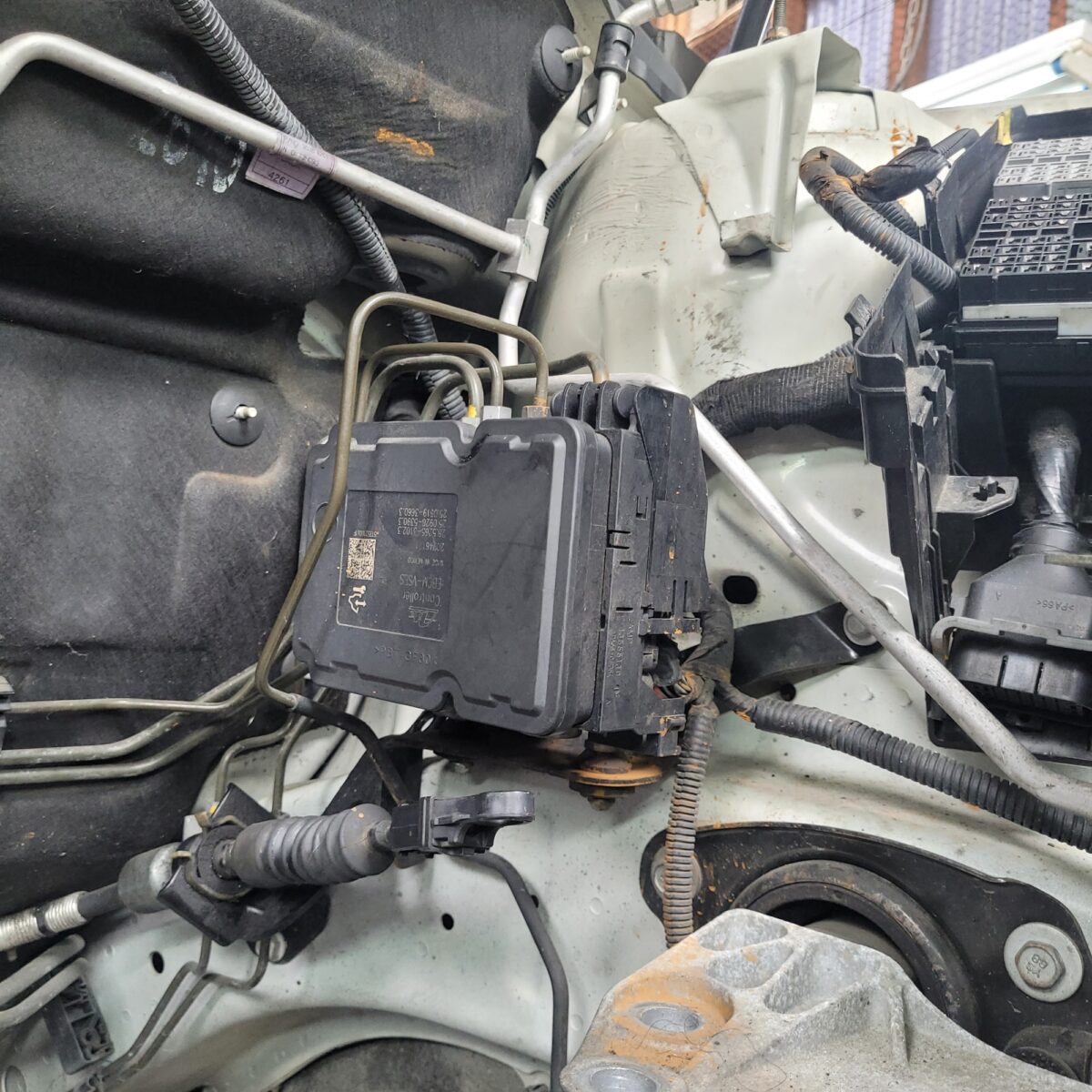

Give the ABS Module Connections a Once-Over

Hamilton’s mix of warm, dry summers and then those soggy, muggy winters on Grey Street mean corrosion can sneak up in the wiring around your ABS module. Whether you’re running a Honda Fit or a Peugeot 308, corroded or loose connections will give you random ABS warnings. Pop the bonnet, check the plugs and wires, and clear any gunk or green stuff off the contacts. Tighten up anything loose, especially if your ABS light comes and goes like it’s playing games.

More on common ABS wiring issues

Read more about ABS module connection issues

Test the ABS Pump and Solenoids

If you’ve got an older BMW X1, a Fiat 500, or even a late-model Toyota Corolla, and your ABS light is still hanging about, we’ll usually test the ABS pump motor and solenoids. These are the bits that help your brakes pulse instead of locking up. Sometimes the pump just stops working — you’ll need a multimeter or get someone like us to check it over properly. If they’re stuffed, they’ll need swapping out.

Discover how to repair an ABS pump motor

Bleed the ABS Brake System

Air in the brake lines is a real killer — especially after jumping potholes along Rototuna or city centre roadworks. If you’ve lost pedal feel after fiddling with the brakes or changing a sensor, get a proper brake bleed. This gets air out of the system and gives you good stopping power again. We see this often with people who’ve had a crack at DIY brake jobs and can’t get rid of that spongy feel.

Learn the importance of brake fluid replacement

Wrap-Up

So there you go — five steps to sort out your ABS light and keep your car safe, no matter if you’re driving school runs through Rotokauri or back and forth to Tamahere. Start with a code scan, clean the wheel sensors, tidy up the electricals, check the pump, and finish with a good bleed. Don’t muck around with ABS faults — it’s all about keeping you and your family safe.

Why Drivers Around Hamilton Trust Grimmer Motors

-

Loads of hands-on experience with ABS systems — from Suzuki Swifts to VW Passats.

-

Qualified techs with the right gear to get to the bottom of the issue, fast.

-

Full diagnostics, WOFs, car service Hamilton, or a quick once-over if you’re not sure what’s up.

-

No surprises — just fair, upfront advice and decent service, every time.

If your ABS light’s still playing up or you just want us to check it over for peace of mind, get in touch — we’ll suss it for you.