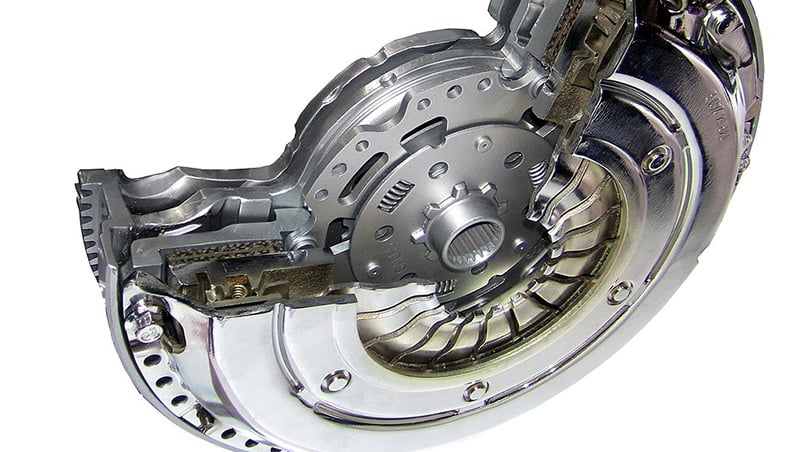

About Dual Mass and Single Mass Flywheels:

In cars with manual transmissions, the flywheel plays a vital role in maintaining smooth engine operation, stabilizing power delivery, assisting in clutch engagement, and facilitating the starting process. Its ability to store and release energy contributes to the overall efficiency and performance of the vehicle.

The main purpose of a flywheel is to dampen the vibrations created by combustion engines when they are starting using the clutch and changing gears. Flywheels evenly disperse the uneven energy they receive from the engine and give it to the transmission.

Difference between Dual and Single Mass Flywheels

Design:

- Single Mass Flywheel (SMF): SMFs consist of a single, solid piece of metal. They are a traditional and simpler design, typically found in older vehicles and some performance-oriented applications.

- Dual Mass Flywheel (DMF): DMFs consist of two connected masses, an inner and an outer part, with a damping mechanism in between. The two masses are connected by springs and dampers, allowing for some degree of independent movement.

Functionality:

- Single Mass Flywheel (SMF): SMFs have a straightforward design and function. They provide a direct connection between the engine and the transmission, transferring energy in a more rigid manner. While this setup is simpler, it can transmit more vibrations and noise to the drivetrain.

- Dual Mass Flywheel (DMF): DMFs are designed to dampen vibrations and reduce noise transmission. The two masses separated by dampers allow for some degree of decoupling, absorbing shocks and vibrations generated by the engine, providing a smoother and quieter operation.

Performance and Comfort:

- Single Mass Flywheel (SMF): SMFs are generally associated with a more direct and immediate response, making them suitable for high-performance applications. However, they may transmit more engine vibrations and noise to the driver and the rest of the vehicle.

- Dual Mass Flywheel (DMF): DMFs prioritize comfort by reducing vibrations and noise, enhancing the overall driving experience. They are commonly used in modern vehicles, especially those with turbocharged engines, where smoother power delivery is desired.

4. Maintenance and Replacement:

- Single Mass Flywheel (SMF): SMFs are typically easier and less expensive to replace. When a single mass flywheel fails, it is often replaced as a unit without the need for complex components.

- Dual Mass Flywheel (DMF): DMFs, due to their more intricate design, can be more expensive to replace. In some cases, the entire DMF assembly may need to be replaced rather than individual components.

Flywheel Maintenance Comparison

After the original dual mass flywheels wears out, they are often replaced or converted to a single mass flywheel. This can be because of the cheaper price of a single mass flywheel. Once worn, dual mass flywheels are very hard or impossible to repair. This is because of the larger number of components in a dual mass flywheel. Unlike a dual mass flywheel, a single mass flywheel has only one part meaning it can be easily resurfaced and repaired. This makes a single mass flywheel more cost effective, as it can be repaired or replaced for a far cheaper price than a dual mass flywheel.

For more information on single mass and dual mass flywheels and flywheel conversion, Feel free to visit any of our other links:

Single and Dual mass Flywheel conversions

Learn more about Flywheels here: Single and dual mass flywheels

Signs and symptoms of flywheel problems:

- Strange Noises: A damaged or worn-out flywheel may produce unusual noises, such as grinding, rattling, or knocking sounds when the engine is running or during gear changes.

- Difficulty in Gear Shifting: Problems with the flywheel can result in difficulties shifting gears, including sticking, jerking, or resistance when trying to engage or disengage the clutch.

- Vibration: A damaged flywheel can lead to increased vibrations, especially during acceleration or when idling. Excessive vibrations may indicate an issue with the flywheel’s balance or integrity.

- Slipping Clutch: A slipping clutch is a common sign of a failing flywheel. If the flywheel’s surface is damaged or if there’s a problem with the clutch disc engagement, it can cause the clutch to slip, resulting in a loss of power transfer to the wheels.

- Burning Smell: Friction generated by a faulty flywheel or clutch can lead to a burning smell, which may indicate overheating and potential damage to these components.

Dual Mass Flywheel Repairs and replacements in Hamilton:

It isn’t rare for flywheels to wear down and need replacement, so at Grimmer Motors, our reliable mechanics can help you with all your flywheel repair and replacement needs.

At Grimmer Motors, we provide a variety of flywheel-related services. This includes Flywheel conversion, replacement, and repair for a range of Flywheels.

For Flywheel repairs in Hamilton, contact Grimmer Motors today!